Product Description

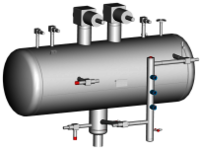

Low Pressure Ammonia Receivers (LPR)

Our organization has gained recognition as an affluent name engaged in offering the best quality L P Receiver. In the manufacturing process of this receiver, our professionals utilize the finest grade raw materials and advance technology. Some of the salient attributes of this L P Receiver is excellent finish, sturdy construction, efficiency, longer service life, easy installation and durability. We assure clients that this receiver is quality tested on predefined parameters to meet the international standards.

MX L.P receiver advantages:

- Even refrigerant distribution

- Pressure drops prevention in system

- Compressors protection from liquid hammer

- Evaporator hot gas defrosting with out disturbing the system

- Protection from fluctuating ambient & condensing conditions

- Ease of operation & low maintenance.

Specification

- Each LP receiver is supplied withMetalexmake high pressure reflex type gauge glass, high and low side liquid floats, Isolation Valves, Duel Safety Valve, Drain Valve and Purge Valve. The receiver is mounted on a sturdy steel structure.

- Inter connecting piping on the skid.

- Working Pressure 6 Kg / CM2.

- Test Pressure 21 Kg / CM2.

Technical Details

Customizable Ammonia SolutionsWe offer Low Pressure Ammonia Receivers that can be tailored in height, width, and length to match your specific industrial requirements. Our manufacturing process ensures each unit delivers optimal performance, reliability, and durability for a wide range of applications.

Superior Material & Quality AssuranceConstructed from high-grade stainless steel, our ammonia receivers resist corrosion and guarantee a long operational life. Every piece is inspected for quality, safety, and compliance with industry standards, providing peace of mind to our clients.

FAQs of Low Pressure Ammonia Receivers:

Q: How are the dimensions of Low Pressure Ammonia Receivers determined?

A: The height, width, and length are customized to your industrial needs, ensuring the receiver fits seamlessly into your facility. You can specify the required dimensions during the ordering process.

Q: What are the main benefits of using stainless steel for ammonia receivers?

A: Stainless steel provides excellent resistance to corrosion and last longer under demanding industrial conditions, making the receivers durable and easy to maintain.

Q: Where are these ammonia receivers typically used in industry?

A: They are predominantly used in various industrial sectors such as chemical processing, cold storage, and manufacturing plants requiring safe ammonia storage and handling.

Q: When should a new Low Pressure Ammonia Receiver be installed?

A: New receivers should be installed when expanding storage capacity, upgrading existing systems, or replacing outdated units to maintain safety and efficiency in ammonia handling.

Q: What is the process for ordering a custom-sized receiver?

A: You can contact us with your specifications for height, width, and length. Our team will assist in selecting and designing the ideal receiver based on your requirements.

Q: How is ammonia safely stored in these receivers?

A: Ammonia is kept under low pressure within the receiver, minimizing risks of leaks and enabling controlled release for industrial processes.

Q: What advantages does sourcing from an India-based exporter, manufacturer, and supplier offer?

A: Working with us ensures direct access to quality products, reliable after-sales service, and timely delivery, supported by local expertise and global export capabilities.